Two robust roller powered with a servomotor ensure accurate feeding and excellent straightening.

Provided the exact size of reinforcement where needed through variable bar size and spacing, thereby reduces steel waste.

Less field labor needed.

Automation instead of manual is more efficient, saving the cost of personnel management management and wage cost.

CNC stirrup bender equipped with a servo system can achieve an accuracy of +/-1mm. The servo system allows for precise control over the movements of the machine, which can be programmed to bend the stirrup into the desired shape with great accuracy. Additionally, the use of computer numerical control (CNC) technology allows for precise and repeatable movements, which further enhances the accuracy of the machine.

CNC stirrup bender equipped with a servo system can achieve an accuracy of +/-1mm. The servo system allows for precise control over the movements of the machine, which can be programmed to bend the stirrup into the desired shape with great accuracy. Additionally, the use of computer numerical control (CNC) technology allows for precise and repeatable movements, which further enhances the accuracy of the machine.

The choice of material for the blades used in a CNC stirrup bender can have a significant impact on the consumption rate and service life of the machine. Blades that are made from high-quality materials such as tungsten carbide or other hard metals are more durable and wear-resistant than those made from lower-quality materials. This can help to reduce the frequency of blade replacements and maintenance, which can save time and reduce operating costs. Additionally, the use of special coatings or treatments on the blades can also help to improve their performance and durability.

Overall, the use of high-quality and durable blade materials can contribute to a lower consumption rate and longer service life for CNC stirrup bender. When choosing the CNC stirrup bender, it’s important to consider the quality of the materials used in its construction, including the blades, in order to ensure the best possible performance and longevity.

XLD CNC stirrup benders to have a double line configuration that allows for the simultaneous bending of two stirrups at the same time. This configuration can significantly increase production efficiency and reduce cycle times compared to the normal machines that can only bend one stirrup at a time.

This feature can be particularly useful for manufacturers and fabricators who need to produce a large volume of stirrups with similar shapes and sizes. By bending two stirrups at once, the machine can complete twice as many parts in the same amount of time, which can help to reduce labor costs and increase production efficiency.

CNC stirrup benders are highly efficient machines that can produce a large number of stirrups in a relatively short amount of time. XLD CNC stirrup benders are capable of producing between 1600 and 1800 stirrups per hour, which equates to almost 7 tons of material per day. This high production capacity can be particularly useful for manufacturers and fabricators who need to produce a large volume of stirrups on a regular basis. In addition to high production capacity, CNC stirrup benders also offer a high degree of accuracy and precision in the bending process, which can help to reduce waste and ensure that the final product meets the customer request.

CNC stirrup benders are highly efficient machines that can produce a large number of stirrups in a relatively short amount of time. XLD CNC stirrup benders are capable of producing between 1600 and 1800 stirrups per hour, which equates to almost 7 tons of material per day. This high production capacity can be particularly useful for manufacturers and fabricators who need to produce a large volume of stirrups on a regular basis. In addition to high production capacity, CNC stirrup benders also offer a high degree of accuracy and precision in the bending process, which can help to reduce waste and ensure that the final product meets the customer request.

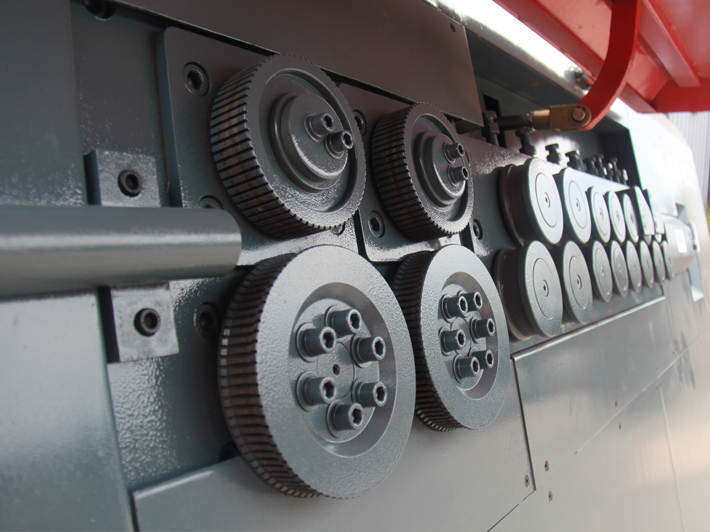

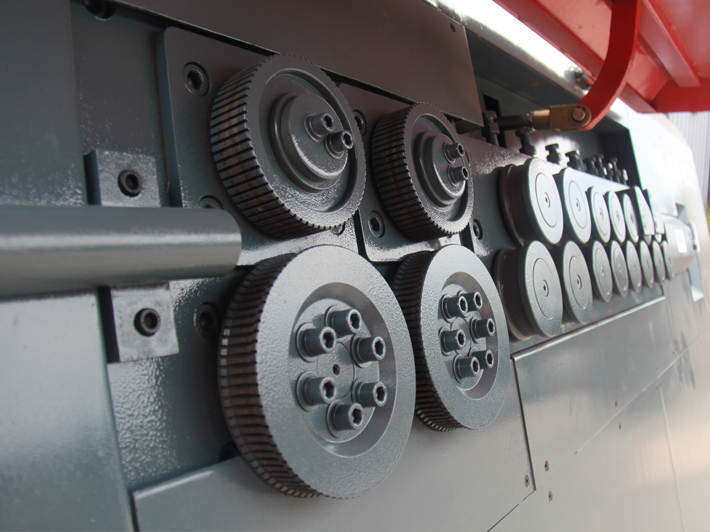

The traction wheels are the important component of CNC stirrup benders as they play a crucial role in the process of sliding and feeding the wire or rebar through the machine. The quality and design of the traction wheels can have a significant impact on the efficiency and accuracy of the bending process. XLD CNC stirrup benders are equipped with traction wheels made from Chromium 12, which is a high-strength alloy that offers excellent wear resistance and durability. The traction wheels are typically designed with a non-slip groove that helps to ensure efficient transmission of the wire or rebar through the machine, while also minimizing the risk of slippage or misalignment.

The traction wheels are the important component of CNC stirrup benders as they play a crucial role in the process of sliding and feeding the wire or rebar through the machine. The quality and design of the traction wheels can have a significant impact on the efficiency and accuracy of the bending process. XLD CNC stirrup benders are equipped with traction wheels made from Chromium 12, which is a high-strength alloy that offers excellent wear resistance and durability. The traction wheels are typically designed with a non-slip groove that helps to ensure efficient transmission of the wire or rebar through the machine, while also minimizing the risk of slippage or misalignment.

CNC is Computer Numerical Control for short, brings many benefits to manufacturing processes. CNC machines are relatively easy to operate, as they only require operators to input the design or CAD (Computer-Aided Design) files into the machine’s computer. This eliminates the need for manual control, reducing the risk of human error and increasing precision. It can perform repetitive tasks with consistent quality and precision, as they follow programmed instructions precisely. CNC controller have a large storage capacity as 400 processing geometric graphics at most.

CNC is Computer Numerical Control for short, brings many benefits to manufacturing processes. CNC machines are relatively easy to operate, as they only require operators to input the design or CAD (Computer-Aided Design) files into the machine’s computer. This eliminates the need for manual control, reducing the risk of human error and increasing precision. It can perform repetitive tasks with consistent quality and precision, as they follow programmed instructions precisely. CNC controller have a large storage capacity as 400 processing geometric graphics at most.

|

Type |

4-12A |

4-14A |

4-14B |

4-14C |

4-14D |

|

Capacity for single line |

4-10 mm |

4-12 mm |

4-12 mm |

4-12 mm |

4-12 mm |

|

Capacity for double line |

4-8 mm |

4-10 mm |

4-10 mm |

4-10 mm |

4-10 mm |

|

Max.bending angle |

+180° |

+180° |

±180° |

±180° |

±180° |

|

Bending direction |

Clock wise |

Clock wise |

Clock wise & Anti-clock wise |

Clock wise & Anti-clock wise(lath) |

Clock wise & Anti-clock wise(lath) |

|

Max.feeding speed |

85 m/s |

85 m/s |

100 m/s |

100 m/s |

100 m/s |

|

Max.length for hoops |

950*950 mm |

1000*1000 mm |

1000*1000 mm |

1000*1000 mm |

1000*1000 mm |

|

Min.length for hoops |

50 mm |

50 mm |

50 mm |

50 mm |

50 mm |

|

Motor power for feeding |

9 kw |

15 kw |

22 kw |

22 kw |

22 kw |

|

Motor power for bending |

3.75 kw |

5.5 kw |

7.5 kw |

7.5 kw |

7.5 kw |

|

Mean power |

4 kw/h |

5 kw/h |

6 kw/h |

6 kw/h |

6 kw/h |

|

Net weight |

1900 kg |

2200 kg |

2300 kg |

3000 kg |

3500 kg |

|

Dimension |

3630*1100*1900 mm |

4150*1220*2040 mm |

4100*2100*1200 mm |

4500*2100*1200 mm |

3800*2000*1500 mm |

Bending Diameter: Rebar 6-25mm

Motor Power: 1600/1700W

Motor Speed: 5-6S

Weight: 109KG

Cutting Diameter: Rebar 4-25mm

Motor Power: 1600/1700W

Motor Speed: 3.5-4.5S

Weight: 32KG

Engine Model: Gasoline HONDA GX160 or B&S 163

Power: 4.0KW / 5.5HP

Working Circle Diameter: 980mm

Weight: 130KG

Bending Diameter: Rebar 6-32MM / Round bar 6-36mm

Motor Power: 3KW-4P

Motor Speed:1440R/MIN

Weight: 270KG

Engine Model: Gasoline / Diesel / Electricity engine

Power: 13HP

Milling width: 250MM

Milling dept: 5-8MM

If you have any inquires about the construction machinery & road machinery, please donnot hesitate to contact us. We will reply you ASAP.