CNC computer panel control the bending angles precisely and automatically.

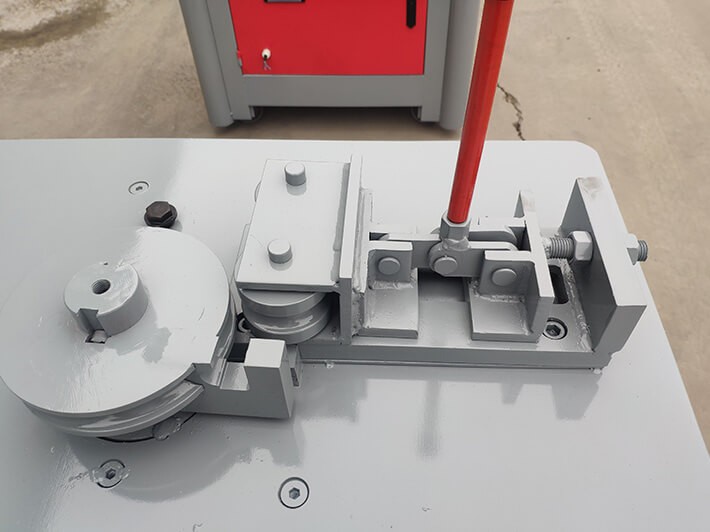

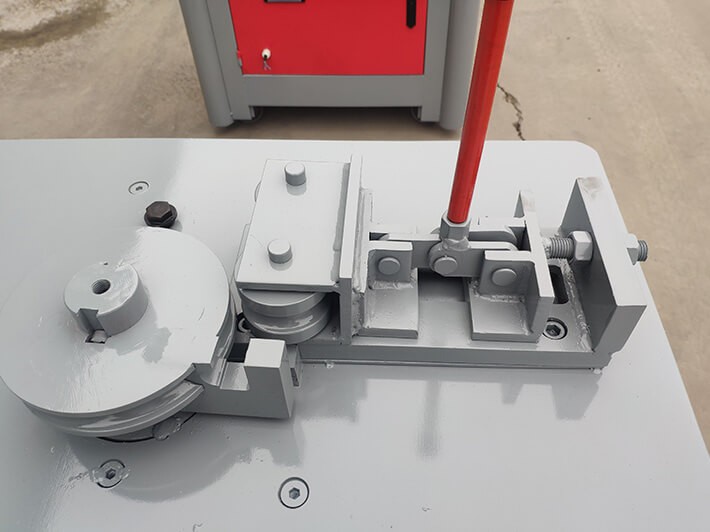

Gear drive is durable and easy maintenance, only need to add the grease oil into the gear box.

Thinner tube and thicker tube also work well by this machine.

Foot switch add CNC operation, makes the tube processing so easy and convenient.

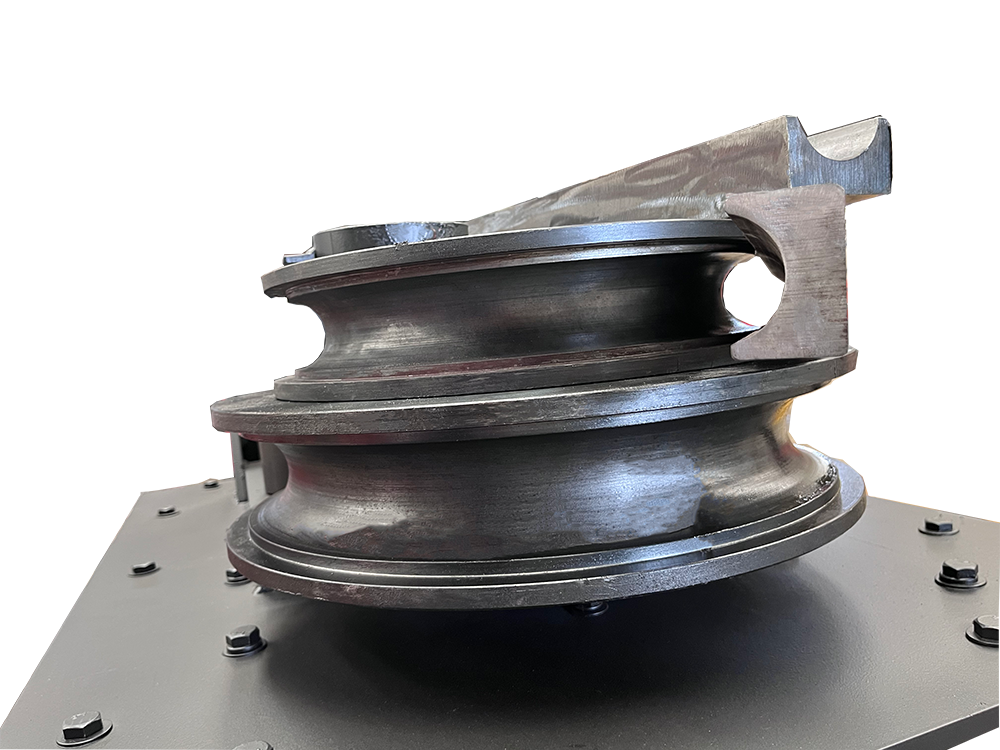

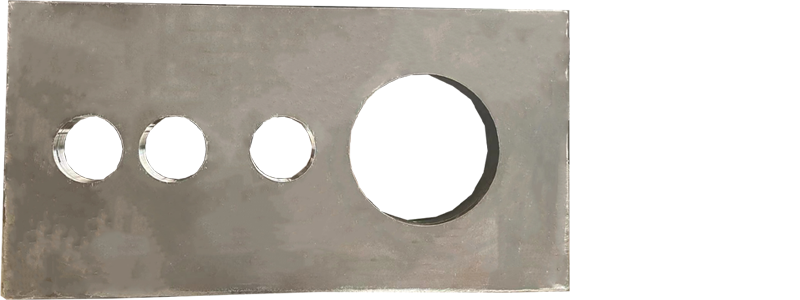

The main component of the Pipe Bender is the Radius Dies & Back Shoes. The bending shoe is a curved or contoured surface that is designed to shape the pipe when pressure is applied. It determines the bend radius and angle of the pipe.

The bending shoe is typically made of 45# steel to withstand the forces involved in the bending process. It comes in various sizes and shapes to accommodate different pipe diameters and bend configurations.

The design of our bending shoe may vary depending on the specific type and model of the pipe bender. Our bending shoes have interchangeable dies, allowing for flexibility in creating different bend radii and angles.

The bending shoe is a critical component of the pipe bender as it directly influences the accuracy and quality of the bends produced. Our appropriate bending shoe and properly aligning the pipe within it, the operator can achieve precise and consistent bends in the pipes.

By employing Micro CNC computer panel control, the pipe bender can achieve high precision, repeatability, and efficiency in their tube bending processes. It ensures consistent quality and accuracy, reducing the need for manual labor and minimizing errors that could occur with traditional bending methods.

The process involves using the CNC computer panel to control the movement and rotation of the tube while it is being bent. CNC pipe bending utilizes computer-controlled machines that precisely execute bending operations according to pre-programmed instructions. It can storage 9 programme at most. This ensures consistent and accurate results across each piece in a manufacturing run. The high level of precision eliminates variations and ensures uniformity in the finished products.

The CNC code generated from the setting from operator. This code guides the machine on how to move the bending head, position the tube, and control the bending process. The automated nature of the process allows for faster and more efficient bending operations, improving overall productivity. This is particularly important for mass production or projects with tight deadlines.

The high-strength properties of steel plate welding contribute to increased durability and longevity of the gearbox. It can better endure the repetitive stresses and mechanical forces experienced during normal operations, resulting in a longer service life with reduced maintenance requirements.

Steel plate welding’s robustness and hardness provide resistance to wear and tear, reducing the likelihood of premature failure or breakdown of gearbox components. This ensures consistent performance over extended periods, enhancing the overall reliability of the machinery.

Despite its high strength, steel plate welding can often be utilized in thinner sections compared to cast iron, leading to reduced weight and overall size of the gearbox. This weight reduction can have positive effects on the overall efficiency and handling of the machinery.

Our professional technical team offers reliable and efficient tube bending machines to meet the demands of each projects. Our technical team would carefully consider the material, diameter, bend radius requirements, and the importance of bend quality for their specific applications, would recommend the suitable options of push bending or mandrel, electricity or hydraulic one.

Push Bending Machine: They are the ideal for bending tubes with larger diameters and thicker walls. We use a bend die to push the tube around a bend form without a mandrel inside. This process works well with softer materials and gentle bend radii.

Mandrel Bending Machine: They are designed to maintain the tube’s internal shape during the bending process by using a mandrel inserted into the tube. Recommended for various tube diameters, from small to large. Suitable for tight bend radii, providing precise and smooth bends. Best suited for applications where the quality of bends is critical, especially in industries like automotive, aerospace, and construction.

The electric pipe bending machine is suitable for applications where the bending requirements are relatively simple and involve pipes with smaller diameters and thinner walls. It is a cost-effective option for light-duty bending tasks, generally easier to operate and require less maintenance compared to hydraulic systems. They are ideal for bending materials like aluminum, copper, and mild steel.

|

Type |

WG24 |

WG32 |

WG48 |

WG76 |

|

Pipe |

Φ14-24mm |

Φ20-32mm |

Φ20-48mm |

Φ30-76mm |

|

Pipe thickness |

1-3mm |

1-4mm |

1-4mm |

1-5mm |

|

Voltage |

380V, Customized |

380V, Customized |

380V, Customized |

380V, Customized |

|

Power |

3KW |

3KW |

3KW |

3KW |

|

Motor speed |

1440r/min |

1440r/min |

960r/min |

960r/min |

|

Bending speed |

20r/min |

20r/min |

16r/min |

16r/min |

|

Weight |

230KG |

260KG |

280KG |

290KG |

|

Dimension |

800*650*900mm |

850*700*930mm |

950*700*950mm |

940*780*960mm |

Engine Model: Gasoline HONDA GX690 or Diesel engines

Power: 17.6KW / 24HP

Working Circle Diameter: 1910mm

Weight: 360KG

Cutting Diameter: Rebar 6-28mm / Round bar 6-32mm

Motor Power: 4KW-3P

Cutting Speed: 28T/MIN

Weight: 510KG

Cutting Diameter: Rebar 4-25mm

Motor Power: 1600/1700W

Motor Speed: 3.5-4.5S

Weight: 32KG

Engine Model: Gasoline HONDA GX160 or B&S 163

Power: 4.0KW / 5.5HP

Working Circle Diameter: 980mm

Weight: 130KG

Engine Model: Gasoline / Diesel / Electricity engine

Power: 13HP

Milling width: 250MM

Milling dept: 5-8MM

If you have any inquires about the construction machinery & road machinery, please donnot hesitate to contact us. We will reply you ASAP.