1. High efficiency design, just one step to finish the rib-peeling process and roll thread process.

2.High threading accuracy, to make sure the connecting easily.

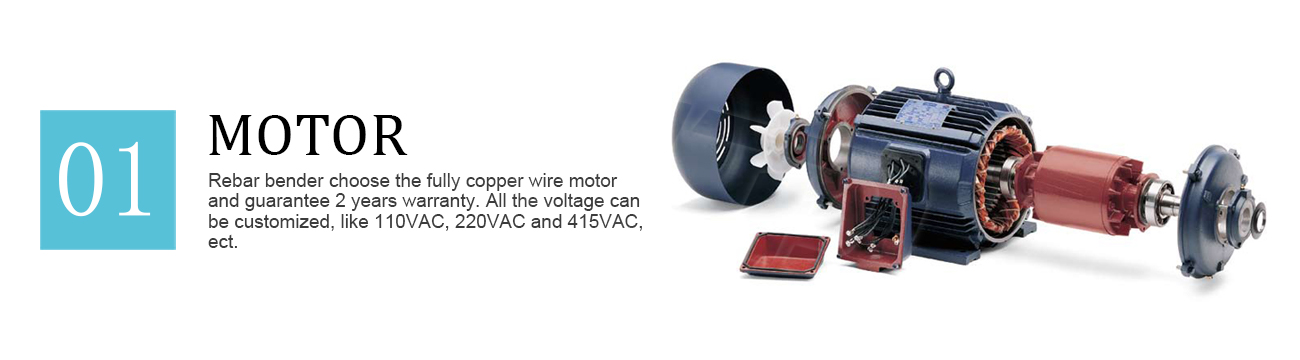

3. Better performance as the pure copper motor and national standard reducer.

4. Operation Power of the machine can be customized.

5. We offer superior quality In our product ranged at Industry Leading Prices.

.

REBAR THREAD ROLLING MACHINE,also called the Rebar threading machine, is used to strip the Rebar rib first, and then roll the thread on Rebar End. It can be finished by one time. After that the two threaded Rebar can be connected by Rebar Coupler. This machine is mainly used to process rebar’s diameter from 16mm to 28mm (for 12mm and 14mm rebar, handpiece should be customized.) and the max thread length could reach 80mm.

|

Model |

HGS-40 |

HGS-50 |

|

Rebar Capacity |

16-28mm |

16-40mm |

|

Motor Power |

4KW |

5.5KW |

|

Speed |

40-62R/MIN |

40-62R/MIN |

|

Processing Length(Max) |

80mm |

80mm |

|

Gross Weight |

280KG |

390KG |

|

Package Size |

1200*500*1050mm |

1200*600*1050mm |

Cutting Diameter: Rebar 4-12MM / Round bar 4-14MM

Cutting Length: 0.3-99m

Cutting Error: ±5mm

Weight: 570kg

Bending Diameter: Rebar 6-32MM / Round bar 6-36mm

Motor Power: 3KW-4P

Motor Speed:1440R/MIN

Weight: 290KG

Bending Diameter: Rebar 6-32MM / Round bar 6-36mm

Motor Power: 3KW-4P

Motor Speed:1440R/MIN

Weight: 270KG

Bending Diameter: Rebar 6-22MM / Round bar 6-25MM

Motor Power: 3KW-3P

Motor Speed: 1440r/min

Weight: 160KG

Cutting Diameter: Rebar 6-32mm / Round bar 6-36mm

Motor Power: 3KW-3P

Cutting Speed: 32T/MIN

Weight: 350KG

If you have any inquires about the construction machinery & road machinery, please donnot hesitate to contact us. We will reply you ASAP.